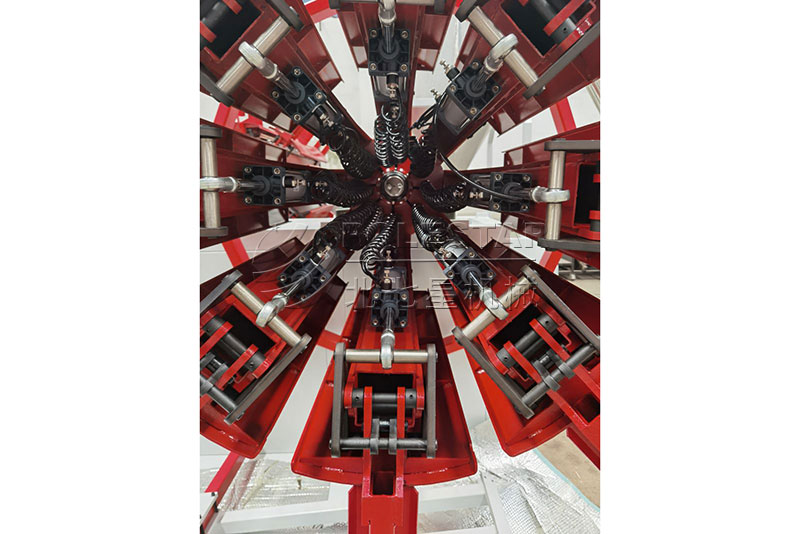

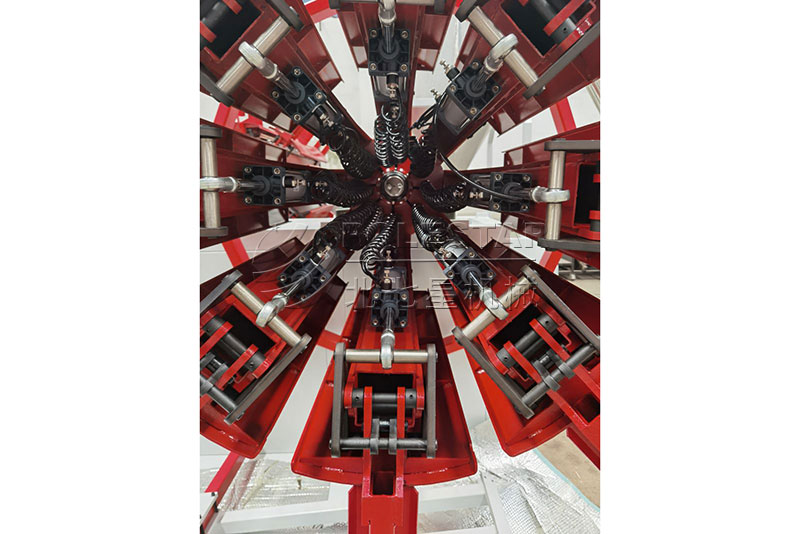

16~63MM Single Station Plastic Profile Winder

Description

Plastic profile winding machine is a specialized piece of equipment designed to wind plastic profiles onto reels in a controlled manner. The primary function of this machine is to accurately and uniformly wind long plastic profiles, such as pipes, tubes, or profiles used in construction, onto reels for storage or transportation.

Some of its key functions include:

Precise Winding: The machine ensures that the plastic profiles are wound evenly and without deformation onto the spools or reels, maintaining their shape and integrity.

Tension Control: It provides adjustable tension control to prevent excessive stretching or distortion of the plastic profiles during the winding process.

Efficient Spooling: The machine facilitates the efficient transfer of the plastic profiles onto reels, optimizing storage and transportation.

Customization: It may offer the flexibility to accommodate different types and sizes of plastic profiles, allowing for customization based on specific production requirements.

Automation: Some machines may feature automation for the winding process, reducing the need for manual labor and increasing productivity.

In summary, the plastic profile winding machine is essential for the manufacturing and processing of plastic profiles, ensuring that they are wound in a controlled and efficient manner, ready for further processing or distribution.

Technical Parameter

- Pipe range: Φ16~63 MM

- Inner diameter: 600~1600MM (adjusted by manual)

- Outer diameter: 2100 MM

- Roll up width: 130~540MM

- Pipe winding speed: 1.5~25 M/Min.

- Main motor power: 1.5 KW

- Wire wind motor power: 0.9 KW

- Air pressure: 3-0.6Mpa

- Speed regulation method:PLC+HMI “DELTA” Inverter