PVC CEILING PANEL PROFILE EXTRUSION MACHINE

Description

The PVC Ceiling Panel Profile Extrusion Line is a specialized manufacturing system designed to produce PVC ceiling panel profiles with precision and efficiency. PVC, or polyvinyl chloride, is a widely used thermoplastic material known for its durability, weather resistance, and aesthetic appeal, making it a popular choice for ceiling applications.

The extrusion line comprises several key components that work together to transform PVC material into ceiling panel profiles. The process begins with the PVC material being fed into an extruder, where it is heated and softened to a viscous state.

Inside the extruder, the PVC material is forced through a die that shapes the material into the desired ceiling panel profile. The die is precision-engineered to produce profiles with accurate dimensions and smooth surfaces, tailored specifically for ceiling applications.

As the extruded profiles exit the die, they are cooled and solidified using a series of cooling rolls. This controlled cooling process ensures that the profiles retain their shape and dimensions while achieving the desired mechanical properties.

After cooling, the ceiling panel profiles are trimmed and cut to the required lengths. Additional finishing operations, such as sanding or polishing, may be applied to further enhance the surface quality and aesthetics of the profiles.

The PVC Ceiling Panel Profile Extrusion Line offers numerous advantages. It produces consistent and high-quality profiles with precise dimensions and smooth finishes. The extrusion process is efficient and scalable, allowing manufacturers to meet varying production demands efficiently. Furthermore, the flexibility of the extrusion line allows for customization, enabling the production of ceiling panel profiles with unique designs and specifications to cater to specific market needs.

Technical Parameter

| PVC Ceiling Width | 200~250 MM | 300 MM |

| Extruder | SJZ51/105 | SJZ55/110 |

| Motor Power | 22 KW | 37 KW |

| Capacity | 100~150 KG/Hr. | 200~250 KG/Hr. |

Production Line Details

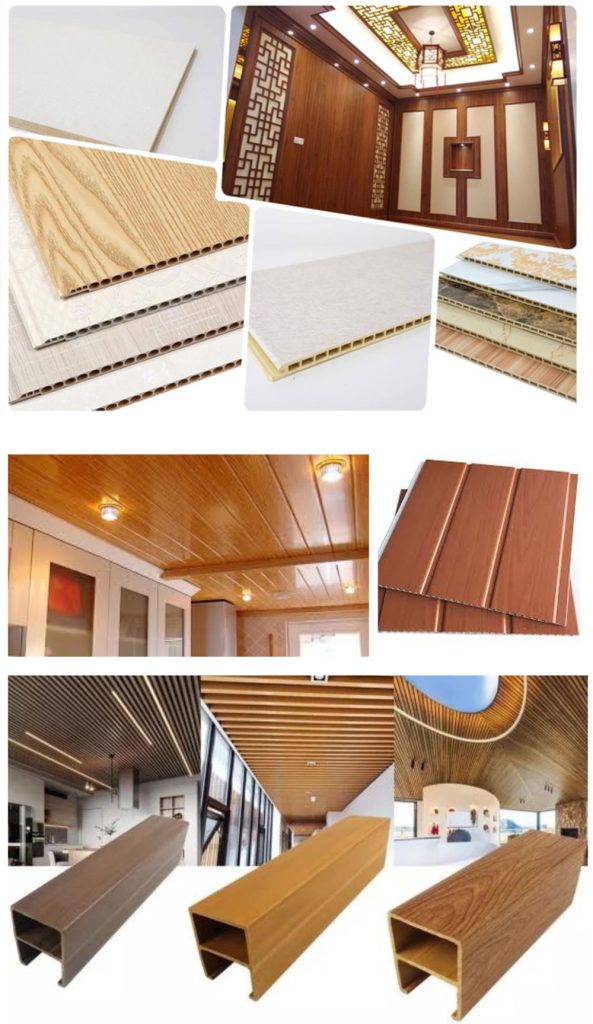

Application